The University of Sheffield is building a 2MW 1MWh smart grid energy store, using novel lithium ion batteries from Toshiba. It will be the UK’s largest grid-connected battery.

The University of Sheffield is building a 2MW 1MWh smart grid energy store, using novel lithium ion batteries from Toshiba. It will be the UK’s largest grid-connected battery.

Funded by the EPSRC, the store will be a research facility for academics and power companies, and the biggest in the UK.

Is purpose it two-fold: power companies can study the use of energy storage on the grid, and it will allow lithium titanate (LiTiO), a relatively new Li-ion material championed by Toshiba, to be evaluated.

LiTiO cells have a longer life than any other Li-ion chemistry, project leader Professor David Stone told Electronics Weekly. And they can be charged far faster than phone batteries.

Toshiba claims over 10,000 cycles (to 20% lost capacity), six minutes to 80% charged, and 15 mins to full chage for the SCiB-branded cells selected by Sheffield. Energy density is 90Wh/kg and 177Wh/litre.

The UK facility is being built at a sub-station near Wolverhampton, owned by project supporter WPD. Aston University is another project partner.

Although it will be the largest in the UK, there are several of similar size grid batteries around the world, and a 40MW 20MWh SCiB battery is due to be operating at Nishi-Sendai sub-station in Japan in 2018.

Although it will be the largest in the UK, there are several of similar size grid batteries around the world, and a 40MW 20MWh SCiB battery is due to be operating at Nishi-Sendai sub-station in Japan in 2018.

For its installation, Sheffield is buying-in a 2MW bi-directional converter from ABB to match the 800V battery to an 11kV power line,

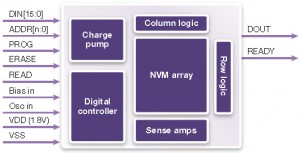

Toshiba is providing the low-level cell and battery monitoring electronics, while Stone’s team and Toshiba are developing the controller that sits between low-level monitoring and the converter.

Experiments are not yet funded, although discussions with electricity suppliers have started.

According to Stone, control strategies for such a battery can be as simple as locally keeping the substation voltage or frequency within specified limits. Remote control will also be possible to allow the national grid to pull its strings.

With a statistically-significant number of cells in the system, experiments could include determining what effects power demand has on the cells and cell balancing, said Stone, as well as how much stabilisation is possible form such a battery, and discovering if there really are business opportunities around grid stabilisation.

Up and running by the end of October, this will only ever be a research tool, said Stone, estimating that the smallest commercial battery would need to deliver 10MW and store 10-20MWh.

Toshiba’s lithium titanate batteries

SCiB batteries are already used in four Japanese grid storage projects, excluding Nishi-Sendai, as well as in two Mitsubishi electric cars and a Honda electric motorbike.

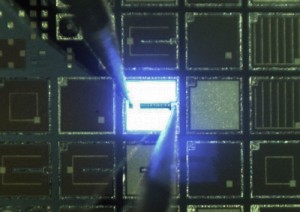

They are built around a 115x103x22mm 20Ah (0.2C) cell for which Toshiba has built a factory with 6GWh/year capacity.

Cell voltage is 2.3V nominal and 1.5-2.7V operating, and internal impedance is 530µΩ.

Continuous discharge is up to 160A, and is “nearly equivalent to ultra-capacitors”, says Toshiba. Discharge is possible from -30 to +55°C.

Charging temperature information is so easy to come by. Automotive versions have been demonstrated charging at 1C at -40°C. Standard laptop Li-ion cells cannot be charged below 0°C.

Unlike laptop cells, they can be crushed with only a low risk of thermal run-away.

The firm takes a modular approach to supplying cells and batteries:

- 24 cells are packed into a 1.1kWh module.

- 22 modules go into a 24kW rack

- 84 racks go into a 1MW 2MWh battery, which occupies 110m2 including switch gear.

At module level, voltage and temperature data is provided to the controller over a CAN bus.