From being a small part of the traditional vacuum cleaner to defining the product itself with the latest robotic vacuum cleaner, Dyson is placing electronics at the heart of its product development plans.

From being a small part of the traditional vacuum cleaner to defining the product itself with the latest robotic vacuum cleaner, Dyson is placing electronics at the heart of its product development plans.

As a result the consumer products company is dramatically expanding its electronics hardware and software development teams and it is building a new R&D centre in the UK to support the growing electronics design activity.

Dyson is a global brand which has reputation of innovating domestic vacuum cleaner design.

There was not much electronics in the original vacuum cleaners. As a result electronics design played a minor role in the development of the first Dyson products.

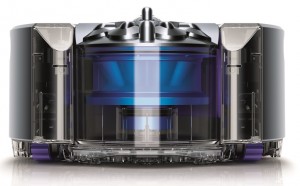

But all this has changed in 2015 with the launch of the Dyson 360 Eye robot vacuum cleaner. Electronics is not only part of the design; electronics defines the product.

Dyson is one of the companies planning to use artificial intelligence and robotics to bring a new level of intelligent computing to the home.

“We have the mechanical and software capabilities, but we still lack understanding – machines that see and think in the way that we do. Mastering this will make our lives easier and lead to previously unthinkable technologies,” says company founder, Sir James Dyson.

Electronics hardware and software design has become an important element in product development at Dyson.

So much so that the company is planning to create a new electronics development centre at its facility in Wiltshire, and the consumer company has a programme to expand its electronics hardware and software development teams significantly this year.

“If we look back at Dyson products over the last 20 years, there was not a lot of electronics in the early vacuum cleaners,” points out Claudio Zizzo global head of electronics at Dyson.

This changed with newer products such as the company’s cooling and heating fans.

“Electronic systems were incorporated for advanced motor control to optimise energy consumption and reduce motor acoustic noise,” explains Zizzo.

“Sir James Dyson was quick to recognise that electronics was no longer just an enabler within the product. With the 360 Eye robot, it is the product,” says Zizzo.

Zizzo, who has strong background in managing electronics design groups at Motorola and Rolls-Royce, was recruited by Dyson almost two years ago to build up the firm’s team of electronics hardware, system and software development engineers.

“The company recognised that electronics was becoming a core element of future product development plans,” says Zizzo.

Dyson is making a major investment to expand its electronics development capabilities.

“In the consumer world the pace of development is very aggressive. Dyson is developing electronics technology on a very fast trajectory and we see a big opportunity to innovate,” says Zizzo.

A new robotics laboratory, which the company is building at its Wiltshire headquarters will open in next two months. The company is in the middle of a recruitment programme which will add hardware, software and systems engineers to its development teams.

Dyson has recruited 60 electronics development engineers in the UK in the last 12 months and Zizzo says there are plans recruit another 70 engineers this year.

The company is looking for engineers with a range of skills and experience. “We are looking for graduate engineers, but also experienced engineers and team leaders,” says Zizzo.

Dyson has also collaborated with Imperial College in the creation of a robotics R&D laboratory at the London university.

With research at the Dyson Robotics Laboratory at Imperial College London, which represents a £5m collaboration between the College and the manufacturer, Dyson is looking to apply the operation of robots beyond controlled environments, such as assembly lines where they work within a strict set of parameters.

The idea is that robots could successfully navigate the real world by interacting safely with their surroundings. To do this it is necessary to develop robots that can process visual information in real-time.

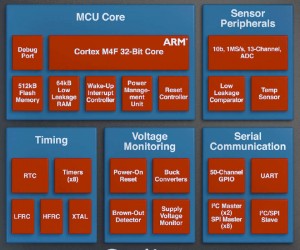

The Dyson 360 Eye has a 360 degree camera and many tens of sensors which are used to model the robot’s environment in 3D. The goal is for robots not only to determine the layout of a room, but also distinguish between objects and determine their purpose.

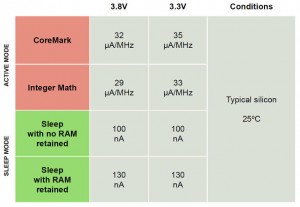

Each house is different, points out Zizzo, so the robot must carry out probabilistic and heuristic analysis of the images and sensor data in real-time, which requires high performance digital signal processing and sophisticated software algorithms.

“A lot of learning takes place in the robot with the aim of getting maximum floor/area coverage with the minimum run time,” says Zizzo.

The electronics design activities within Dyson incorporate analogue and power circuit design as well as embedded processor systems design. There is advanced motor control for the four drive motors in each robot, for example as well as radio frequency circuit design for the Wi-Fi system.

Dyson is also developing its own software to control and operate the robot. The software development team numbers 55 people and is growing rapidly.

The software and connectivity team is also responsible for the development of the smartphone apps which are used to operate the robot.

The company which has expanded its horizons from vacuum cleaner design to robotics is not planning to stop looking for new areas in which it can innovate.

Last November, Dyson announced its plans for a £1.5bn investment for future technologies, including a £1bn for the research and development of new product technologies.

Zizzo believes electronics design will become a major element of future product development at the company.

“The products that come after this first robot will have even greater levels of electronics within them,” says Zizzo. “There is an electronics revolution taking place at Dyson,” says Zizzo. “I believe that anyone joining the company now is joining Dyson at a very exciting point in time.”