Printed polymer sensors change look and feel of IoT

Printed polymer sensors look like being the next big thing in IoT device technology.

At Sensors Expo in California this week Hoffmann+Krippner demonstrated how sensors based on printed polymer pastes can be accurate enough for IoT position or pressure sensors.

The sensor materials called SensoInk can be printed as potentiometers, resistors, switches or keyboard contacts on circuit boards or electronic components.

Only two components are required for signal transformation: a printed potentiometer track on a carrier material (e.g. FR4 or PET foil) and a conductive wiper.

The firm also has a membrane position sensor called Sensofoil, which is a thin-film membrane 0.5 mm to 1 mm thick.

It is available in lengths of 50 mm up to 500 mm, 40mm wide rotary. The supplier claims a repeat accuracy of 1mm to 10µm.

Jens Kautzor, CEO of Germany-based Hoffman+Krippner writes:

“To detect how the state of the internet-connected “thing” changes, an electronic evaluation of the initial state must be conducted. With our sensors you can accurately measure changes, detect positions, or count objects.”

Another firm Thin Film Electronics has demonstrated a printed sensor for tagging bottles which can detect when a product is “sealed” and “open”.

Likely to be used for tagging wine and spirits, pharmaceuticals, cosmetics and automotive fluids, the tag is designed to provide NFC-readability before and after a factory seal on the product has been broken.

According to the Norway-based company, it is possible to provide content to mobile devices on “sealed” or “opened” status, as the consumer’s context shifts from “pre-purchase” to “in use.”

For example, a sealed product could trigger multimedia content to encourage a consumer purchase, while opened products could deliver messaging with usage tips and recommendations of complementary products.

An attraction of the printed NFC tags is that the can be produced at lower cost than traditional radio-frequency identification (RFID) devices, said Thin Film Electronics

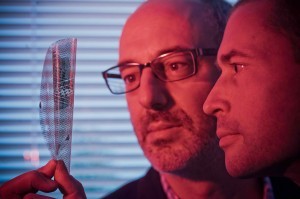

Cambridge-based PragmatIC, which recently received a cash injection from investors such as ARM and CIC, said it has plans to broaden its circuit design activities, including applications such as sensors, processors and wireless communications.

PragmatIC has a production facility based at the National Centre for Printable Electronics in Sedgefield, is using the funding to hire more staff and to enable the scale-up of its production capacity to 100 million flexible integrated circuits later this year.

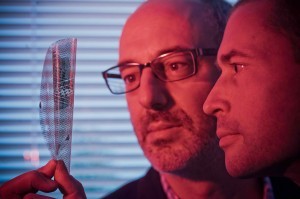

Scott White, CEO, PragmatIC (pictured right), says the company now has the funding to address the limitations of how robustly and cost-effectively create printed electronic devices for e-passports and other applications.

Scott White, CEO, PragmatIC (pictured right), says the company now has the funding to address the limitations of how robustly and cost-effectively create printed electronic devices for e-passports and other applications.

“Our technology platform creates a microcircuit thinner than a human hair that can be easily embedded in any flexible surface,” said White.

According to Victor Christou, senior investment director of CIC, PragmatIC’s flexible electronics offers “the most compelling and cost effective product I’ve seen in the 20 years I’ve been involved in this industry.”

Richard Wilson