Military hardware has adopted the practices of the commercial market to enjoy the benefits of open standards, modular system architectures and software-defined radio, write Nigel Forrester and Paul Moakes

Military builds on open standards and SDR – CommAtility’s conduction-cooled board

In the embedded industry, there is over 30 years’ experience of using open standards based building blocks in defence applications. Suppliers accept that it takes a lot of trust for a defence equipment manufacturer to choose COTS (commercial-off-the-shelf) components. Longevity of supply, high quality manufacture and testing, and the ability to support equipment in the field are critical attributes that suppliers must demonstrate.

Once trust is established, the benefits of modular building blocks based on open standards can be realised. For military deployment, while there still needs to be system-level qualification, each block that can be sourced off‑the‑shelf saves time to deployment, reducing development cost and risk.

Off-the-shelf with open standards

The ability to intercept, monitor and decode communications must keep pace with constantly evolving threats. While COTS technologies are not always available, they provide a valuable choice with shorter design cycles.

Armed forces need the most capable software defined radio/electronic warfare (SDR/EW) equipment. COTS parts make it easier to update standards-based equipment, provided the standards in question are widely supported. There has been a proliferation of open standards, as more industries and markets have become aware of the advantages. They can broadly be split into three categories:

- those applicable for low cost, single processor systems

- multiprocessor architectures driven by a small group of manufacturers

- multiprocessor architectures driven by a wide group of suppliers and end users.

EW/SDR equipment needs multiple, connected processing elements, so naturally falls into the last category. Several open standards could be considered suitable, including CompactPCI Serial and Rugged MicroTCA from the PICMG standards body, plus VITA’s VME and VPX standards.

Embedded benefits

CompactPCI boards and AdvancedMC modules (used in MicroTCA systems) do not yet have sufficient momentum in the defence community and so are not seen as the best choice, despite having some technical merits.

Many VME boards have been deployed in military and aerospace, and this could still be a valid option for updating an existing system. However, the obvious choice for a new design is the VPX portfolio of standards.

VPX was originally introduced as VITA 46 and then augmented with the OpenVPX VITA 65 initiative. VITA 46 offers great flexibility in pinout choices, negating some of the advantages of COTS hardware by allowing vendors to create unique solutions.

VITA 65 was driven by customers’ need to standardise on defined profiles for interoperability, and has stimulated a wave of VPX deployments, where it is now the de-facto choice, allowing ‘best-in-class’ modules to be selected from alternate vendors.

Backplane mapping within a VPX solution is important. Although governed by a set of predetermined slot profiles in the specification, a choice of backplane architectures is available for implementation. The VITA 65 specification defines profiles in an exact way.

Electronic warfare

A configuration suitable for EW includes a single Intel control processor mated with several DSP/FPGA cards via a PCIe and Ethernet switch. An example for command and control is the TR B1x/msd board from Concurrent Technologies, which is based on a fourth generation Intel Core processor.

The board has two x4 PCIe data plane “fat pipe” connections, compliant with the VITA 65 MOD3-PAY-2F2U-16.2.3-3 profile. In the profile “2F2U” refers to having two fat pipes (four lanes) for data plane use plus a pair of ultra-thin (one lane) pipes for control use. The end digits identify the two fat pipes as PCIe Gen 2 compliant, and the two ultra-thin pipes as 1,000Base-BX control plane interfaces.

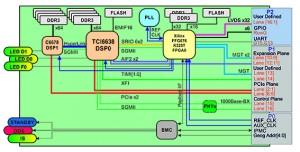

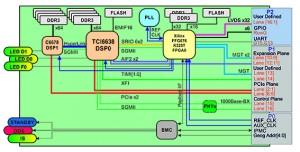

Figure 1: VPX-D16A4-PCIE block diagram showing rear I/O

Four CommAgility VPX-D16A4-PCIE DSP/FPGA boards (Figure 1) are used for signal processing, and also have PCIe connectivity. The two DSPs on each board have their own x2 PCIe connections out to the backplane, and so the TR B1x/msd control board is configured with an x4 data plane bifurcated into two x2 pipes. This allows data to be sent between individual DSPs and the command and control board.

Smaller, lower cost VPX configurations can be created without the switch module, by using a backplane that has specific connectivity, for example with a single Intel‑based control processor having an x4 PCIe connection to two DSP/FPGA boards in the slots either side of the CPU.

Rugged kit

Many EW/SDR deployments must work in a conduction-cooled, rather than air-cooled environment, tolerate high levels of shock and vibration and have a coating to protect against factors like moisture and pollution.

The VPX-REDI specifications (VITA 48.0) assure ruggedisation in COTS-based military systems and focus on aspects that allow favourable size, weight, and power (SWaP) metrics.

Nigel Forrester is technical marketing manager at Concurrent Technologies and Paul Moakes is technical director at CommAgility

Richard Wilson