Researchers at Mitsubishi have created custom mosfets for an all silicon carbide 3.3kV 1.5kA dc to three-phase traction inverter for railway trains, claiming the inverter to be a world first.

Researchers at Mitsubishi have created custom mosfets for an all silicon carbide 3.3kV 1.5kA dc to three-phase traction inverter for railway trains, claiming the inverter to be a world first.

The company has already operated a hybrid design with silicon IGBTs and 1.7kV SiC Schottkys on an underground train, which demonstrated 38.6% power savings compared with the conventional system.

Custom 3.3kV 1.5kA SiC mosfets and Schottky diodes were created for the all-SiC project, and built into modules with one transistor and one diode. In all, the inverter has 16 modules. Switching losses in the inverter are claimed to be 55% better than the silicon equivalent.

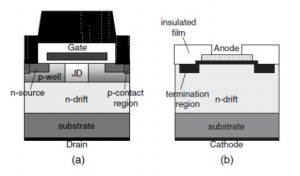

To get conduction losses as low as equivalent silicon IGBTs, mosfet cell structure was optimised, and the JFET region (‘JD’ in the diagram) of the mosfets was n-doped by high energy nitrogen implantation to reduced JFET on-resistance at high temperature.

For stable avalanche breakdown (~4kV), a field-limiting ring structure was developed for edge termination in both devices.

Also for stability, the reverse diode inherent in the mosfet structure was optimised for a long working life carrying current alongside the Schottky, rather than needing to be shorted by the Schottky.

Final mosfet active area is 0.83cm2, and the Schottkys each cover 0.74cm2.

Report ‘3.3kV/1500A power modules for the world’s first all-SiC traction inverter‘ in the Japanese Journal of Applied Physics describes the SiC semiconductors.

The research is also featured in the September 2015 issue of the JSAP Bulletin, from which the diagrams are taken.

steve bush