Researchers at the University of Southampton will attempt to make novel optical fibres using 3D printing.

Researchers at the University of Southampton will attempt to make novel optical fibres using 3D printing.

To make glass optical fibres, a block of glass called a ‘pre-form’ is heated close to melting point and pulled so that it gets longer and thinner – a process called ‘drawing’.

The fibre inherits characteristics from the pre-form, so for a traditional fibre the preform starts as a cylinder of glass with a high refractive index core along its centre.

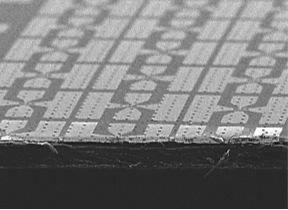

Southampton is a world leader in advanced fibres which have complex features – doping profiles and voids running their length, for example.

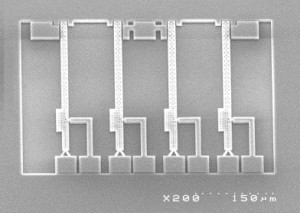

The latest are ‘microstructured’ fibres, where fibres with a certain internal structure are precisely stacked into a bundle, and then the bundle is drawn, and the process perhaps repeated, to produce a fibre fractal-like complexity – it is this process that was used to produce the microstructured ‘microchannnel plates’ used in second-generation image intensifiers.

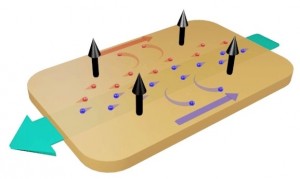

Photonic bandgap fibre, for example, is a type of microstructured fibre which is hotly anticipated by the telecoms and datacoms industries, said the University, and 3D-printing might allow micro-structured pre-forms to be made in one step.

“We will design, fabricate and employ novel ‘multiple materials additive manufacturing’ [MMAM – 3D printing] equipment to enable us to make optical fibre preforms in silica and other host glass materials,” said Professor Jayanta Sahu of the University of Southampton’s Zepler Institute. “Our proposed process can be utilised to produce complex preforms, which are otherwise too difficult, too time-consuming or currently impossible to be achieved by existing fabrication techniques.”

The Zepler Institute is a multidisciplinary centre for photonics, electronics and quantum technologies – directed by Professor Sir David Payne, whose team invented the erbium-doped fibre amplifier (EDFA) in the 1980s.

Preforms tens of centmetres long will be built layer-by-layer using ultra-pure glass powder.

There are numerous challenges, including the need for precise control over dopants, refractive index profiles and waveguide geometry, as well as the high melting temperature of glass – over 2000˚C for silica. The transitions between the layers also have to be smooth to avoid corrupting the resultant fibre.

The Engineering and Physical Sciences Research Council (EPSRC) is providing funding for the project, which will involve three companies: Oxford-based laser material processing systems firm ES Technology, Southampton speciality fibre maker Fibercore, and Cambridge optical fibre equipment supplier SG Controls.

“This is something that has never been tried before. We hope our work will open up a route to manufacture novel fibre structures in silica and other glasses for a wide range of applications, covering telecommunications, sensing, lab-in-a-fibre, meta-material fibre, and high-power lasers,” said Sahu.

The photo shows the Zepler Institute fibre drawing tower.