XP Power EPL225

XP Power has revealed design features within its latest ac-dc power supply, dubbed ELP225, which can deliver 150W convection-cooled from a 51 x 102mm industrial ‘1U’ footprint package.

Only 32.3mm high, this is believed to be a power density record for the 1U open frame format. 225W is available with 10CFM forced airflow (see later).

Higher efficiency has allowed so much power to be squeezed through such a small package, according to company technical director Gary Bocock. “Once you get to 90% efficiency, every 1% more efficiency means 10% less heat,” he told Electronics Weekly. And every per cent is worth it because “with 2x4inch supplies there is only so much surface area to dissipate power.”

Another reason to maximise efficiency in the supply is to avoid using a fan. “People don’t want to use a fan,” said Bocock. “Audible noise level is the biggest problem today, particularly in medical, or bits get blown into the power supply, or air filters need replacing, and fans wear out.” Although, he added, fan wear is not the problem it once was.

Efficiency

Efficiency peaks at 95% and remains above 90% for every combination of input and output voltage from 20% to 100% load.

Even with wide efficiency curve, efficiency has to peak somewhere, and the design is optimised to position this peak at the maximum convection-cooled output power.

“We tried to make it truly 150W when convention cooled: for 90 to 264Vac input, and all the way to 50°C ambient so ours can be used anywhere worldwide. Some products in market de-rate at low Vin, or are only rated up to 40°C ambient,” said Bocock.

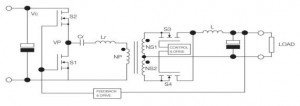

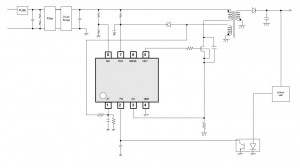

The topology of the main converter is resonant ZVS LLC (zero voltage switched inductor-inductor-capacitor, see diagram), where Lr in the diagram is actually the leakage inductance of the transformer.

The topology of the main converter is resonant ZVS LLC (zero voltage switched inductor-inductor-capacitor, see diagram), where Lr in the diagram is actually the leakage inductance of the transformer.

With resonant topologies, points out Bocock, the important reactances tend to be the parasitics that do not make it onto conventional circuit diagrams.

ZVS LLC is variable frequency, increasing filtering complexity, but over a narrow range, which eases the situation.

LLC half-bridge is a popular topology around this power level, but knowing that is just the first step in making a good power supply. “The theory is one thing, implementation is another,” said Bocock.

Output rectification is synchronous with mosfets to save power compared over the diode alternative. The active half-bridge secondary uses two winding and two mosfets. “I have not seen anyone use a full bridge secondary,” said Bocock.

One reason for this is the awkward gate drive needed for a four mosfet bridge.

Output mosfets are cooled by the considerable heatsink visible in the photo, which has grown since XP’s previous 2x4inch PSUs. These used similar rectification technology, but only had to deliver 120W with convection cooling or 180W forced.

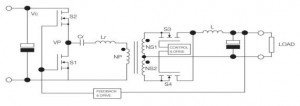

Quasi-resonant power factor correction

The main power stage is preceded by a transition-mode quasi-resonant power factor correction (PFC) stage. This mode is discontinuous – current reaches zero – with the switch turning on at the bottom of the decaying voltage sinusoid – so not zero voltage switching but minimum voltage switching.

Topologies and design are chosen to minimises electrical noise because of its indirect effect on both physical size and power efficiency.

“If you want a very efficient power supply, you need to start from low noise because all those filters and snubbers waste energy,” said Bocock. Attention to noise generation allows filtering circuits in ELP225 to be fairly simple, he said.

Conducted and radiated noise meet the standards EN55011 and EN55022 for Class B conducted and Class A radiated EMI specifications.

According to Bocock, XP typically aims for an EMI noise margin of 6dB under standard test conditions to allow customers some leeway.

Somewhere else the customer needs a little flexibility is cooling as not everyone has access to thermal modelling or a heat expert. “Some just get the largest fan they can fit,” said Bocock.

An initial estimate of ambient temperature could be way out, or most of the air from a fan could go somewhere else.

Down-to-earth thermal design

To bring these issues down to earth, XP identifies critical points on the PSU to be measured once it is in the prototype. “The whole airflow thing is very difficult to predict. In the data sheet, we say measure the temperature of some specific components and make sure they do not get above temperature. If the temperature is lower than specified, it will meet all safety requirements,” said Bocock. “We recommend the customer always measures the temperatures of the electrolytics, just in case ambient is actually high, and we always try to put electrolytic life curves in the data sheet.”

For reference, for convection cooling XP measures its open frame flat, with the PCB at the bottom. This is probably the harshest orientation except for upside down, said Bocock. If they are mounted vertically or sideways, they are likely to run cooler. For forced air testing, PSUs are installed in a duct of around 40x75mm cross section.

The series comprises seven standard models with outputs from 12 to 48V. All also have a second (12V 500mA) output to drive a fan.

Supplied from 230V, average efficiency is 93% across the range (average of efficiencies with loads of 25, 50, 75 and 100% of 225W).

With no-load power consumption is less than 500mW.

Intended for industrial, IT and medical applications, the series complies with EN 60950-1 for IT equipment plus medical approvals ANSI/AAME/ 60601-1 and IEC/EN60601-1 3rd edition.

Temperature range is -20 to 70°C, derated above 50°C, warranty is three years, and the approved altitude limit is 5,000m.

Stockists include: Farnell element14, Digi-Key and XP Power.

steve bush