Fairchild has launched an isolated dc-dc controller chip which adds current-mode control to LLC resonant power supplies.

Called FAN7688, it has ‘charge current control’, instead of the voltage mode control traditionally used for LLC. “This “allows for tighter and faster output regulation against load transients and also simplifies the control loop,” said Farichild.

Update: see below for more technical detail, courtesy of Fairchild.

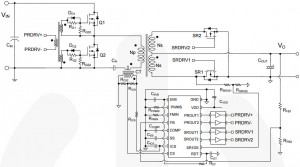

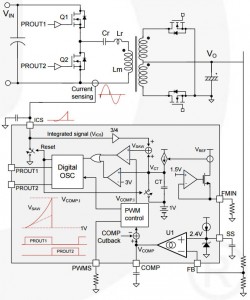

The technique involves combining a triangular waveform from the oscillator (see below) with the integrated switch current information to determine switching frequency, providing “a better control-to-output transfer function of the power stage simplifying the feedback loop design while allowing true input power limit capability”, said Fairchild.

Closed-loop soft-start prevents saturation of the error amplifier and allows monotonic rising of the output voltage regardless of load condition.

For improved efficiency, output rectification is synchronous using adaptive dead time control to reduce body diode conduction time – something branded ‘adaptive dual edge tracking secondary side synchronous rectifier control’.

Efficiency for a for 400V in and 12V out power supply is “typically up to 97%”, according to a Fairchild FAN7688 video – (interesting after a slow start)

Operating frequency spans 39-690kHz, and the chip works over -40 to +125°C.

Protection includes over-load, over-current, output-short and over-voltage.

Applications are expected in servers, telecoms, industrial, PCs and TVs.

There are two evaluation boards: 306W FEBFAN7668 and 250W FEBFAN7688A.

A little more detail

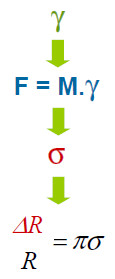

Primary-side switch current does not increase monotonically in resonant converter due to the sinusoidal current waveform, so it cannot be used for pulse frequency modulation (PFM) for output voltage regulation. Also the switch peak current, according to Fairchild, does not reflect load current because of large circulating currents included in the switch current.

Primary-side switch current does not increase monotonically in resonant converter due to the sinusoidal current waveform, so it cannot be used for pulse frequency modulation (PFM) for output voltage regulation. Also the switch peak current, according to Fairchild, does not reflect load current because of large circulating currents included in the switch current.

However, the integral of primary side switch current (the primary charge) does increase monotonically and it’s peak value reflects the load current properly.

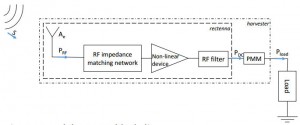

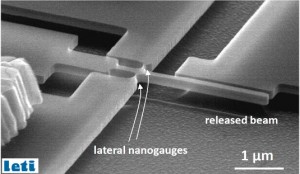

Primary side switch current is sensed through the current transformer (see diagram) – whose output is coupled to the FAN7688 and reset by the chip during half of the switching cycle to generate a proper charge signal. Then, this charge is compared with the control voltage to modulate the switching frequency.

Charge is proportional to average input current over a switching cycle, so it provides a fast inner loop with excellent transient performance including inherent line feed-forward.

CT, the PFM block timing capacitor is charged with a current set by the resistor on pin FMIN. Sawtooth waveform VSAW is the sum of the integrated primary current and and the timing capacitor voltage. This sum is compared with the compensation voltage to determine the switching frequency. Minimum switching frequency is set by a 3V limit in CT.

At light load, where circulating currents would be high, switching is shifted to PWM control.

Why use LLC, Fairchild explains:

The LLC resonant converter has been widely used becaus it can regulate the output over load variations with a relatively small variation of switching frequency.

It can achieve zero-voltage switching for the primary-side switches and zero-current switching for the secondary rectifiers over the entire operating range.

The resonant inductance can be integrated with the transformer into a single magnetic component.

Voltage-mode is typically used, where the error amplifier output voltage directly controls the switching frequency, However, compensation is relatively challenging since the frequency response with voltage control includes four poles and the locations of the poles changes with input voltage and load.

Charge current control is described in detail in the FAN7688 data sheet functional description section.