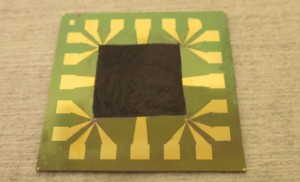

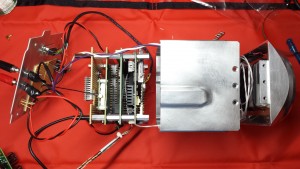

The miniature prototype entry vehicle for interplanetary exploration, called the Micro-Reentry Capsule (MIRCA)

Source: NASA/Goddard

Low cost miniature satellites could one day be used to orbit and explore distant objects such as planets and comets.

Nasa is investigating the feasibility of sending CubeSats out of earth orbit to investigate distant objects.

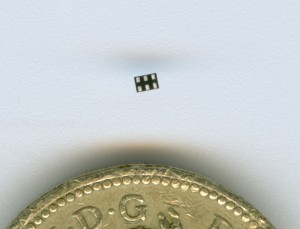

The hope is that this will dramatically reduce the cost of sending probes to investigate such objects as Comet 67P/Churyumov-Gerasimenko, which has been explored by the Rosetta mission. Rosseta’s comet lander, called Philae, is the size of a large domestic appliance. CubeSats, by contrast, are about the size of a loaf of bread.

Jaime Esper and his team at Nasa’s Goddard Space Flight Center in Maryland are planning to test the stability of a prototype entry vehicle, the Micro Re-entry Capsule (MIRCA), this summer during a high-altitude balloon mission.

Planetary missions

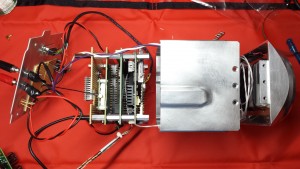

Dubbed the CubeSat Application for Planetary Entry Missions (Cape), the concept involves the development of two modules: a service module that would propel the spacecraft to its celestial target and a separate planetary entry probe, which could survive a rapid dive through the atmosphere of another planet, all while transmitting scientific and engineering data back to Earth.

“The Cape/MIRCA concept is like no other CubeSat mission,” Esper said. “It goes the extra step in delivering a complete spacecraft for carrying out scientific investigations. We are the only researchers working on a concept like this.”

The Cape/MIRCA spacecraft, including the service module and entry probe, will weigh less than 4.9Kg and have dimensions of 10cm³.

CubeSats being released from the International Space Station in an earlier mission

It would be ejected from a canister housed on its mother ship and would have its own solar panels to power it on its journey to another planetary body.

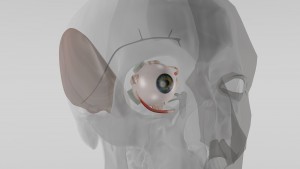

Once it reached its destination, the sensor-loaded entry vehicle would separate from its service module and begin its descent through the target’s atmosphere.

It would communicate data about atmospheric pressure, temperature, and composition data to the mother ship, which then would transmit the information back to Earth.

Multi-point sampling

The attraction is that cubesats are relatively inexpensive to build and deploy, scientists could conceivably launch multiple spacecraft for multi‑point sampling – a capability currently not available with single planetary probes that are the Nasa norm today, said Esper.

So the first step is demonstrating a prototype of the MIRCA design during a balloon mission this summer.

According to the plan, the capsule, manufactured at Nasa’s Wallops Flight Facility on Virginia’s Eastern Shore, would be dropped from a balloon gondola at an altitude of about 30km to test the design’s aerodynamic stability and operational concept.

During its free fall, MIRCA is expected to reach speeds of up to Mach 1, roughly the speed of sound.

“If I can demonstrate the entry vehicle, I then could attract potential partners to provide the rest of the vehicle,” said Esper.

The next step, says Esper, may be to drop the entry vehicle from the International Space Station, perhaps as early as 2016.

This would expose the capsule to spaceflight and the heat of atmosphere re-entry.

Richard Wilson