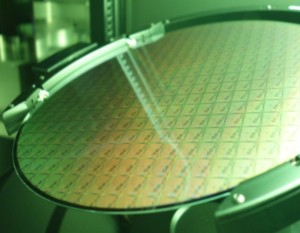

AMS Fab B, top right

Smart sensor firm ams is going from strength to strength.

With a number of high-profile design-ins in the mobile and wearables markets, including the Apple Watch, the Austria-based semiconductor company has expanded is presence in the Asian market.

It has opened a new office in Pangyo, South Korea to address the growing market for mobile and biotech.

This follows the opening of a design centre in Japan.

The company has also recently expanded its chip testing facility in Calamba City, Philippines, in response to growing global sales on the back of the Apple Watch design-in.

According to Jong Duck Lee, Korea country manager of ams, the company will concentrate on providing “more strategic and closer support to our customers as it is recognized as one of the most cutting-edge and advanced industrial complexes and is located near leading manufacturers in Korea.”

“This demonstrates a commitment to provide continuous investments and efforts in growing the local presence in the region as well as an appreciation of the strategic importance of the Korea market.”

In May, ams announced that automotive equipment supplier Marquardt is using its AS3914 NFC reader IC in a range of contactless door lock and ignition control modules.

Marquardt is a supplier to many big name car manufacturers around the world.

The expansion of the ams chip testing facility in Calamba City means an increase of 130% in size and will result in a total net production area of 10,000m².

The building will test assembled analogue ICs, sensors and sensor interfaces for the automotive, medical, industrial, and consumer electronics industries.

Thomas Stockmeier, chief operational officer at ams said:

“As a global leader in analogue ICs and sensor solutions, we are proud to have the skill and dedication of our Philippines workforce with currently 500 people and we are excited to see the new investment underlines our confidence in our overall growth strategy.”

This year the firm claimed to have the smallest ambient light sensor which uses through-silicon via (TSV) packaging to achieve a footprint of just 1.145 x 1.66mm and a height of 0.32mm.

The TSV package does not need wire bonds and provides a direct connection from the device I/Os to a solder ball.

According to David Moon, senior marketing manager in the Advanced Optical Solutions division of ams:

“With a footprint of less than 2mm2 and a height of only 0.32mm the TSL2584TSV marks a major milestone in the development of ALS solutions, opening up many new options for implementing display management in highly space-constrained designs.”

Richard Wilson

Atmel is the latest semiconductor supplier to tap into the internet of things (IoT) opportunity with the creation of cloud services to support its MCUs and wireless chips.

Atmel is the latest semiconductor supplier to tap into the internet of things (IoT) opportunity with the creation of cloud services to support its MCUs and wireless chips.