The search for millimetre wave expertise

There is a flurry of activity in the various research teams developing technology for the 5G generation of mobile communications around the world .

The trigger seems to be to build know-how in millimetre-wave radio technologies which will operate around 60GHz.

Keysight Technologies is to work with Japan’s main mobile operator NTT Docomo on 5G communication system development.

In the UK, Bristol start-up Blu Wireless Technology has joined the University of Surrey’s 5G Innovation Centre (5GIC) as part of its SME Technology partner programme.

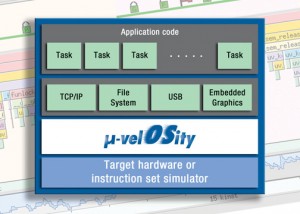

This follows the announcement earlier this week that Imagination Technology was also contributing semiconductor IP and developers to the Surrey-based 5GIC.

5G now looks like being a game-changing development in mobile communications and it will require big technology changes from the semiconductor level to network architectures. Because of this test is a major element in the early development of the 5G standards.

The 5GIC in the UK already has test firms Cobham and Rohde & Schwarz among its partners.

Keysight’s collaboration in Japan will involve multiple 5G research areas including millimetre-wave (mmWave) communications technology, which plays a major role in enabling 5G.

Lower power millimetre wave transmission is being considered for 5G because of the scarcity of spectrum resources below 6GHz, which leads to high interference levels, the public concern about microwave electromagnetic field (EMF) exposure in dense areas and the power consumption of the infrastructure.

According to Dr. Laurent Dussopt, MiWaveS project manager and Leti research engineer: “the flexible spectrum usage of the mmW frequency bands at 60GHz and 71-86GHz will enable data transmissions up to 10Gbit/s for backhaul and 5Gbit/s for mobile users access”.

According to Seizo Onoe, chief technology officer of NTT DOCOMO:

“NTT DOCOMO is targeting a 5G commercial launch in 2020, and we expect the partnership with Keysight, and use of its deep measurement expertise, will allow our mobile communication industry to gain insight into the capabilities of 5G technologies faster.”

Keysight is presenting its 5G technologies including millimeter wave channel sounding, ultra wideband and massive MIMO measurements, at the 5G Tokyo Bay Summit this week.

“5G has aggressive performance goals that will be addressed with multiple enabling technologies including mmWave frequencies, ultra-broad bandwidths, massive MIMO, and new air-interfaces,” said Jay Alexander, Keysight’s chief technology officer.

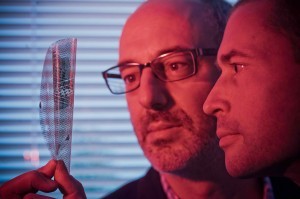

Blu Wireless will bring its millimetre wave gigabit modem expertise to the 5GIC mobile testbed.

The official launch or the 5GIC on the University of Surrey campus is due in September. It is the UK’s main 5G technology initiative and includes companies such as BBC, BT, Cobham, EE, Fujitsu, Huawei, Rohde & Schwarz, Samsung, Telefonica and Vodafone.

Mark Barrett, Blu Wireless CMO, said:

“The 5GIC is a global centre of research into next generation wireless networks and we are delighted to be a part of it. Our technology will enable 5G infrastructure and access applications such as radio transport over Back Haul and Front Haul networks and will help to drive the research that will underpin the 5G standards of the future.”

According to Professor Rahim Tafazolli, director of 5GIC, with Blu Wireless joining the Centre, its capabilities are further strengthened particularly in millimetric band technologies.

“We look forward to integrating their equipment and expertise into our new test bed, housed on our campus in Guildford.”

Richard Wilson